Three-phase brushless DC motor optimization solution based on STMicroelectronics STEVAL-LVLP01 and B-G473E-ZEST1S

STEVAL-LVLP01 solution supports ZeST and HSO algorithms. This solution can be connected to the STM32 control board B-G473E-ZEST1S through the motor control connector V2.

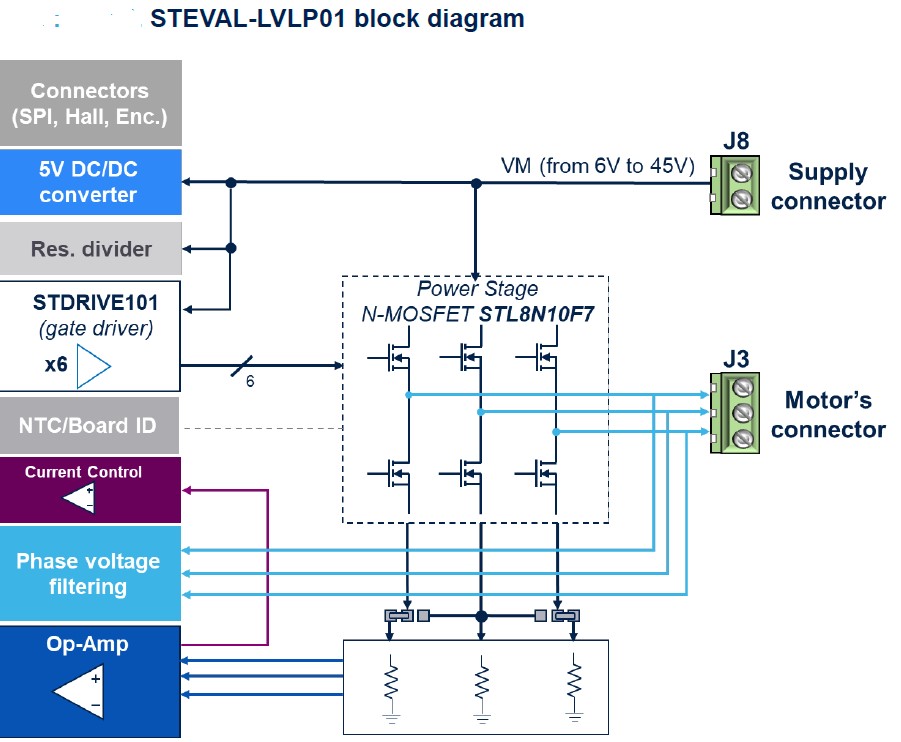

The STEVAL-LVLP01 solution is based on the STDRIVE101 three-phase gate driver and STL8N10F7 power MOSFET. Built-in power stage and circuitry for driving three-phase brushless DC motors.

Users can use it with B-G473E-ZEST1S to enable ZeST and HSO algorithms on STM32 microcontrollers.

STEVAL-LVLP01 can support single-channel or three-channel shunt operation. Onboard motor position feedback and motor phase detection networks use separate connectors to implement sensor and sensorless algorithms for motion control.

ST STMicroelectronics has released the STM32 ZeST* (zero speed full torque) software algorithm. The algorithm runs on an STM32 microcontroller, allowing the sensorless motor driver to produce maximum torque at zero rpm.

This algorithm provides zero-speed, full-torque motor control for the first time in a general-purpose motor drive, enabling previously unachievable smoothness and predictability of motor operation.

Products and equipment such as power tools, electric curtains, washing machines, automatic lawn mowers, air conditioning systems, electric bicycles, etc. require the motor to start with maximum torque in the correct direction and/or start quickly with maximum load, while consuming minimal electrical energy. Ordinary non-inductive motor drives cannot determine the rotor position of the motor at zero speed and, therefore, cannot meet the requirements of these devices. Previously, ensuring accurate positioning, high energy efficiency and correct operation usually required the addition of hardware position sensors or the use of special types of motors.

The new STM32ZeST software algorithm is a universal solution for zero-speed sensorless motor control optimization, supporting any type of permanent magnet synchronous motor (PMSM). In order to achieve optimal control, the STM32ZeST algorithm needs to run synchronously with the newly launched High Sensitivity Observer (HSO) algorithm, using a sensorless non-inductive mode to control motor operation. As an embedded software solution, there is no need to install additional hardware or special peripherals on the STM32 microcontroller (MCU). To ensure that the motor control remains energy efficient, the resistance of the motor is also estimated at runtime.

By using the STM32ZeST and HSO software algorithms, designers can avoid high peak currents during startup and improve the energy efficiency of their applications. Compared to motor drivers with Hall sensors, ST's solution reduces bill of materials (BOM), improves operational reliability, and reduces noise. STMicroelectronics has developed a demonstration model showing how an inductive motor drive can be activated to move a load at various speeds and at minimum speed. This model uses an electric pedal wheel to demonstrate that the motor always starts in the intended direction and can keep the load stationary at zero speed.

In order to facilitate developers to evaluate the performance of the STM32ZeST and HSO algorithms and speed up development progress, STMicroelectronics has developed supporting hardware tools. Among them, the B-G473E-ZEST1S control board generates PWM signals for the power supply board STEVAL-LVLP01. The power strip drives low power/low voltage motors, such as those found in STMicroelectronics' B-MOTOR-PMSMA kit. The connection between the control board and the power board uses the new embedded motor control connector V2.

STMicroelectronics provides developers with extensive additional support services to help them create drives for popular motor types that meet a variety of application requirements and meet energy efficiency, size, performance and cost constraints. The STM32 family of microcontrollers meets a variety of performance needs, and many products integrate features suitable for motor control, such as advanced motor control PWM timers. All of these products are supported by the STMicroelectronics Motor Control Software Development Kit (MC-SDK). The suite includes a motor control firmware library and a dedicated configuration tool (Motor Control Workbench). Both tools need to be used in conjunction with the STM32Cube ecosystem and the STM32CubeMX project configurator.

The HSO algorithm is integrated in the new version of MCSDK (version 6.2) development kit. The new version of MCSDK adds a dual-driver solution running on STM32 G4 MCU, and also supports various series of STM32 microcontrollers from the cost-effective STM32C0 to the high-performance STM32H5.

For more information on STM32 motor control, and to download the new MCSDK v6.2 including HSO software algorithms, please visit https://www.st.com/en/embedded-software/x-cube-mcsdk.html

Scenario application diagram

Display board photo

Scheme diagram

Core technical advantages

1. Get higher torque performance than traditional sensorless solutions

2. Improve end-user experience at startup (no need to brake for back-EMF reading)

3. Energy saving (lower peak current)

4. Maintain high performance even at extremely low speeds

5. Convenient configuration through user-friendly interface

6. Achieve seamless transition between STM32 ZeST and HSO

Solution specifications

• STDRIVE101 triple half-bridge gate driver

• STL8N10F7 N-Channel 100 V STripFET F7 Power MOSFET

• Single or three-way split operation